UW Madison Division of Extension Dodge County has launched a new effort to support Dodge County residents especially during these uncertain times. We are calling it “FROM THE DESK OF EXTENSION-(article topic)”. This will be a weekly article covering topics from our programmatic areas of agriculture, families, youth, and food/nutrition. The articles will address current issues facing residents through the lens of those program areas. Thank you for supporting our mission to bring relevant research based information and education to the residents of Dodge County.

Pattie Carroll, Human Development & Relationships Educator | Extension Dodge County

Spring is in the air and you know what that means? It is time to pull out your home food preservation pressure canner and make sure it is in good working condition before the canning season starts.

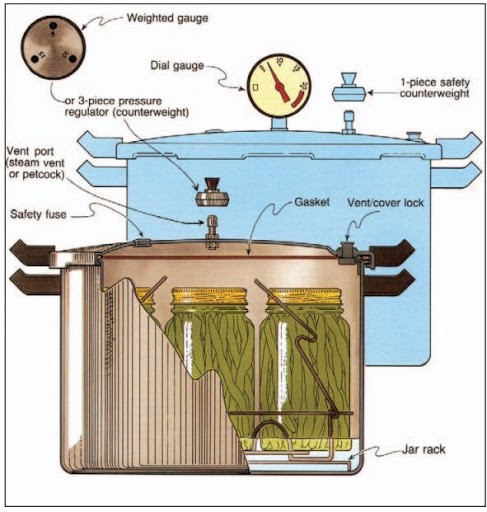

First a little background. There are two types of pressure canners. A dial gauge for indicating the pressure or a weighted gauge, for indicating and regulating the pressure. Regardless of the type of canner you have, the USDA recommends that a canner be large enough to hold at least 4-quart jars standing upright on the rack, with the lid in place. A pressure canner must be able to regulate pressure at 5, 10 and 15 pounds of pressure. The canner should have a way to follow recommended venting procedures to remove air from inside the canner before it is pressurized, and to indicate that the canner remains at least at the target pressure throughout the entire process time. Some newer models of canners hold an extra layer of pint jars, with the two layers of pint-size jars separated by a rack called a double stack.

Weighted gauges are usually designed to “jiggle” several times a minute or to keep rocking gently when they are maintaining the correct pressure. Read your manufacturer’s directions to know how a particular weighted gauge should rock or jiggle to indicate that the proper pressure is reached and then maintained during processing. People who prefer to use a weighted gauge canner often like knowing that they can hear the canner weight jiggle or rock as a signal that it is working properly.

Dial gauge canners will usually have a counterweight or pressure regulator for sealing off the open vent pipe to pressurize the canner. This weight should not be confused with a weighted gauge and will not jiggle or rock as described for a weighted gauge canner. Pressure readings on a dial gauge canner are only registered on the dial. Dial gauge canners are easy to use and individuals who prefer to use a dial gauge canner like knowing that they are following the pressure recommended in a recipe.

Safety is important. Check dial gauges for accuracy each year, even if the gauge was not used or has never been used (brand new!). Gauges that read high cause under-processing and may result in unsafe food. Low readings cause over-processing. Pressure adjustments may be recommended if the gauge reads up to 2 pounds high or low.

Where to have your dial gauge checked. Here are two options for checking a dial gauge.

- Presto will test gauges for Presto canners and Presto-associated brands at no charge to consumers. Consumers do need to mail the gauge to Presto for calibration. Contact Presto Industries (Eau Claire, WI) for more information: 715-839-2121 or 800-877-0441.

- UW Division of Extension Dodge County; call for an appointment- 920-386-3790.

Remember, regardless of the type of canner that you use, be sure to always follow an up-to-date, research-tested recipe.